Filtration Grade: F7-F9

Filter Media: High-performance synthetic fiber

Structure: Folding structure, perfectly combining high efficiency and low resistance, without damaging the original system, easy to install, maintain and replace.

Main Applications:Aimed at office indoor environment renovation, in line with the relevant requirements of GB51039-2014.

Aerospace Field

AGF’s Clean Pleasure series products provide health protection for flight

Aerospace Field Solution

Challenges Posed by Air Pollution in Aerospace Field

With the vigorous development of China’s aerospace industry, the hazards of air pollutants in the aerospace field have gradually attracted attention.

Oil-based Particles

Incomplete combustion of aircraft exhaust leads to massive emissions of oil-based particles into the air. These particles not only affect air quality but may also damage aerospace equipment.

Poor Filtration Efficiency of Conventional Consumables

Conventional consumable-based filtration solutions have poor effectiveness and cannot efficiently filter pollutants from the air.

High Daily Operation and Maintenance Costs

Traditional air filter consumables often have limited filtration efficiency and short replacement cycles, increasing operation and maintenance costs. The daily operation and maintenance costs of terminal air filtration systems are also an important consideration.

AGF CleanPleasure Series: Dedicated to Providing Reliable Technical Solutions in Aerospace Field

The AGF CleanPleasure series air filters feature excellent particulate matter filtration capabilities, efficiently removing oil-based particles to protect aerospace equipment and passenger health.

·Using long-life filter materials, CleanPleasure air filters not only demonstrate superior filtration efficiency but also have a longer replacement cycle, significantly reducing operation and maintenance costs.

·With a reasonable design, CleanPleasure air filters are easy to maintain and replace, reducing the labor intensity of maintenance personnel. Meanwhile, their long life and high-efficiency filtration performance also reduce the replacement frequency of consumables, further lowering operation and maintenance costs.

·Strengthen monitoring and management of particulates, air volume, and resistance. Air Guard has built a sound environmental monitoring system that provides real-time data solutions for various gaseous pollutants, such as PM2.5, CO₂, TVOC, formaldehyde, temperature, and humidity. Through real-time data monitoring, it enables a better understanding of the real-time data of fresh air air conditioning systems and air quality, allowing more precise adjustment of the coordinated use of each system.

AGF’s Practical Application Solutions and Advantages:

High-efficiency Filtration: Adopts advanced filter materials and technologies to ensure efficient removal of particulates and pollutants in the air.

Stable Performance: Undergoes strict quality control to maintain stable filtration performance in various environments.

Long Service Life: Uses long-life filter materials to reduce consumable replacement frequency and lower operation and maintenance costs.

Easy Maintenance: Reasonable design facilitates maintenance and replacement, reducing the labor intensity of maintenance personnel.

Wide Application: Suitable for various aerospace scenarios, including terminal buildings, aircraft cockpits, and the interior of spacecraft.

The AGF CleanPleasure series air filters provide efficient air purification solutions for the aerospace field with excellent filtration performance and stable quality. Whether facing challenges of oily pollutants or issues such as poor filtration efficiency and short replacement cycles of conventional consumable-based solutions, the CleanPleasure series can always offer satisfying answers.

Aerospace Field Related Productions

Fan Coil Return Air Outlet

Coarse Efficiency Panel Filter

Filtration Grade: G3~M5

Filter Media: Double-layer synthetic fiber

Structure: Diversified structural design to adapt to the needs of multiple application scenarios

Continuous Operating Temperature: ≤68℃

Recommended Final Resistance: ≤250 Pa

Main Application: Suitable for pre-filtration devices of air intake and exhaust systems in air conditioning units.

Performance Features: Low initial pressure drop, long service life, particulate matter removal efficiency >90%

Flame Retardancy: Meets German industrial standard DIN53438 F1

Coarse-Medium Efficiency Bag Filter

Filtration Grade: M5~F9

Filter Media: Pure polypropylene (PP) material

Structure: “Siming System” progressive structure with gradient deep-layer filtration, dust holding capacity 2.5 times higher. Global patented large-wave nano-fiber design for high dust holding capacity, replacement cycle over 2 times that of melt-blown solutions. Physical barrier filtration, no release of harmful substances including ozone, no spark generation. Chemical fiber filter materials are non-toxic and harmless.

Main Application: Suitable for filtration of intake and exhaust systems in airport air conditioning units and fresh air systems.

Performance Advantages: 40% lower resistance (at the same efficiency level), annual consumable replacement costs, manual maintenance costs, and disposal costs reduced by over 50%.

Standards Compliance: Meets EN779/ISO16890/GB/T14295 and other standards. Fire test: European ISO11925-2 (most stringent grade).

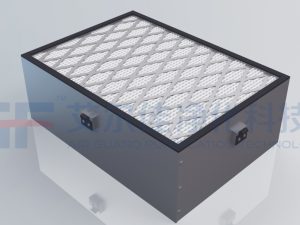

V-type Filter

Filtration Grade: F8~E12

Filter Media: Double-layer High-density Glass Fiber Material

Structure:

“W” shaped structure with air outlet surface protective mesh.

Continuous Operating Temperature: ≤68℃

Recommended Final Resistance: ≤650 Pa

Main Application:

Suitable for terminal high-efficiency filtration of intake and exhaust systems in airport air conditioning units and fresh air ventilation systems.

Features:

Low initial resistance, long service life, high burst strength.

Particle removal efficiency >99.5%.

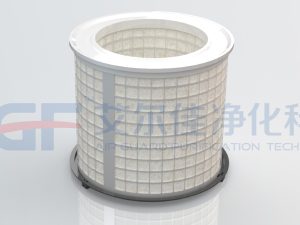

Aircraft Onboard Primary Efficiency Filter

Filtration Grade: Initial gravimetric efficiency ≥ 90%

Filter Material: Synthetic fiber material

Structure: Standard cylindrical structure. Adopts glue pouring process to ensure that the upper and lower end caps are sealed without leakage. The finished product meets the UL94 V0 flame retardant requirement. Filter design standard: EN 779:2012.

Main Application: Suitable for filtration of the intake and exhaust systems of aircraft air conditioning systems.

Aircraft Onboard Parted Filter

Filtration Grade: Initial gravimetric efficiency ≥70%

Filter Material: Synthetic fiber material

Structure: Aluminum foil is inserted into the middle of the parted filter. The filter is folded by a paper pulling machine and adopts glue pouring technology to ensure sealed without leakage. The finished product meets the UL94 V0 flame retardant requirement. Filter design standard: EN 779:2012.

Main Application: Suitable for filtration of the intake and exhaust systems of aircraft air conditioning systems.

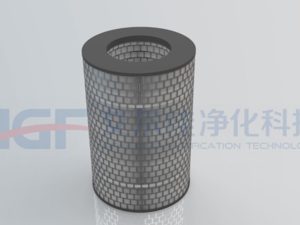

Aircraft Onboard HEPA Air Filter

Filtration Grade: H13

Filter Media: Glass Fiber Material

Structure:

Standard cylindrical structure, adopting gluing process to ensure sealed upper and lower end caps without leakage.

The finished product meets the UL94 V0 flame-retardant requirement.

Design standard: EN 1822-2019.

Main Application:

Suitable for filtration of intake and exhaust systems in aircraft air conditioning ventilation systems.

Function Description:

The primary function of HEPA filters is to filter and purify external air, reducing the spread of bacteria and viruses during flights and enhancing passenger comfort and safety. Through the filtration of HEPA filters, over 99.97% of particles (for 0.3-micron particles) can be effectively retained, thus significantly improving the cleanliness and safety of in-cabin air.

Aircraft Onboard HEPA Air Filter

Filtration Grade: H13

Filter Media: Glass Fiber Material

Structure:

“W” shaped structure, featuring large air volume intake matched with high filter media area.

Adopts gluing process to ensure sealed leakage-free performance.

Finished product meets UL94 V0 flame-retardant standard; design compliance: EN 1822-2019.

Main Application:

Suitable for filtration of intake and exhaust systems in aircraft air conditioning ventilation systems.

Filtration Performance:

The HEPA filter effectively retains over 99.97% of particles (for 0.3-micron particles) through its filtration mechanism, significantly enhancing in-cabin air cleanliness and safety.

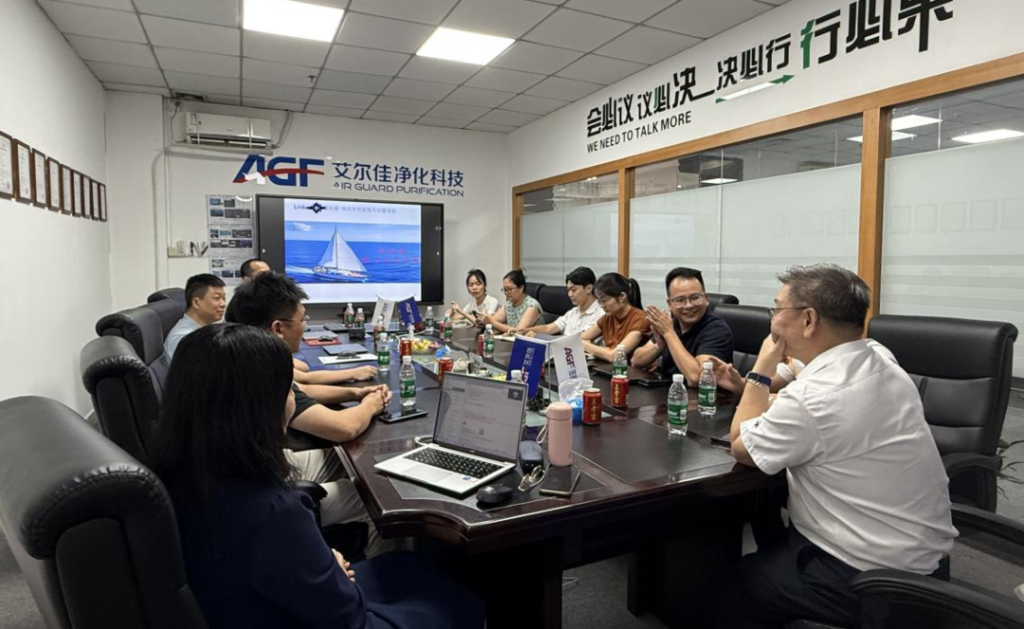

A Grand Commencement: AGF Technology Industrial Park Project Breaks Ground, Setting New Benchmarks in Purification Industry and Embarking on a New Journey of Strategic Collaboration

Air Guard Purification Technology (Guangdong) Group Co., Ltd. (hereinafter referred to as “Air Guard”) and Guangdong Yuebiao Construction Co., Ltd. (hereinafter referred to as “Yuebiao Construction”) recently held a grand kick-off meeting for the “Electromechanical and Interior Fit-out Project of the Air Guard Technology Industrial Park.” This ceremony marks the official commencement of a significant collaborative project following the establishment of their strategic partnership, further deepening and broadening their cooperation within the purification sector. Senior executives from both companies attended the launch event to witness this pivotal milestone.

Figure 1: Group Photo at the Project Kick-off Meeting

Air Guardian: From Technological Breakthroughs to Industry Leadership

As a benchmark enterprise in China’s purification industry, Air Guard is consistently committed to providing global clients with multi-domain, multi-scenario air purification and filtration products, alongside innovative technological solutions. Its expertise spans critical sectors including automotive intelligent cockpits, aerospace, rail transit, chips & semiconductors, life sciences, and data centers.

In innovation and R&D, Air Guard has established profound industry-university-research collaborations with South China University of Technology and Guangdong University of Technology. Together, they have founded joint industry-university-research bases, an Advanced Air Purification Filtration Materials R&D Center, a Joint Laboratory for Filtration Materials and Application Technologies, a Postdoctoral Workstation, a Scientific Expert Workstation, and university joint training bases. By integrating the R&D and application of high-performance key materials for air purification, the company continuously drives the innovation and application of advanced filtration technologies in fields such as new energy vehicles, industrial environments, healthcare, food processing, animal husbandry, commercial buildings, public spaces, and rail transit.

Figure 3: Signing of the Strategic Partnership Agreement

This new project is built upon a solid foundation of mutual trust. As early as February 2025, Yuebiao Constructin successfully undertook the electromechanical project for Air Guard’s new factory in Thailand, earning high praise from Air Guard for its exceptional engineering quality and efficient project management. Building on the success of that project, the two parties formally signed a strategic cooperation agreement in June 2025, establishing a long-term, stable partnership.

Strategic Synergy: Building a New Industry Benchmark Together

At the kick-off meeting, Senior Executive Mr. Ma of Air Guard emphasized in his address that the Air Guard Technology Industrial Park is a core strategic vehicle for the company to perfect its full-industry-chain layout in the purification field. He stated that the electromechanical and interior fit-out project, being a critical part of the park’s construction, directly impacts the future operational efficiency and production environment quality of the park. His decision to once again partner with Yuebiao Construction signifies full confidence in their professional capabilities and represents a further deepening of their strategic alignment.

Mr. Li, General Manager of Yuebiao Construction, expressed that his company deeply understands Air Guard’s stringent requirements for engineering quality. For this electromechanical and fit-out project, Yuebiao Construction will uphold its spirit of “dedicated precision and relentless pursuit of excellence,” fully leveraging its professional expertise in industrial construction to ensure the high-quality delivery of the project.

Alumni Power · Cross-Border Expansion | Unlocking New LinkedIn Customer Acquisition Channels, Discussing New Opportunities in Global Trade

DONGGUAN, CHINA – On the afternoon of September 19, 2025, a dedicated alumni salon for South China University of Technology (SCUT) alumni, initiated by LinkToken – a LinkedIn-focused international trade client acquisition service provider, and supported by Air Guard Purification Technology (Guangdong) Group Co., Ltd., was successfully concluded in Dongguan. Centered on the theme “Solving International Client Acquisition Challenges: Efficiently Developing Global Customers with LinkedIn,” the event attracted over ten alumni from diverse industries, all united by their focus on business globalization, to explore new pathways for cross-border growth.

The session featured a comprehensive sharing session led by Ms. Xiao Shiyue, Founder of LinkToken and a fellow SCUT alum. As a seasoned global business expert with over 20 years of hands-on experience in international trade, Ms. Xiao has previously guided her teams to achieve annual sales exceeding RMB 1 billion. She specializes in LinkedIn B2B customer development and global branding strategy. During the event, she systematically outlined a full-funnel methodology for leveraging LinkedIn—from account setup and content operation, to precise prospect searching and conversion follow-up—supplemented by real-world case studies from various trading companies, providing attendees with highly actionable strategies. The sharing revolved around five core modules:

- Pain Points in Global Expansion & The Strategic Edge of LinkedIn

- Building High-Conversion Profiles and Crafting a Powerful Personal IP

- Precise Target Customer Identification and Templates for Effective Outreach

- Content Strategy, Engagement Techniques, and Data-Driven Optimization

- Low-Cost Launch Strategies and Long-Term Operational Risk Mitigation

During the open networking segment, participating alumni, whose expertise spans manufacturing, technology, and other sectors, engaged in vibrant discussions on topics including overseas market penetration, team capability building, and content localization. Many attendees expressed that such pragmatic salons, initiated by alumni and backed by corporate support, truly foster “experience sharing and resource connectivity,” offering clear and viable new perspectives for the transformation of traditional trade and the journey of brand globalization.

As the supporting organization for this event, Air Guard Purification Technology Group provided an excellent communication environment and industry networking opportunities for attending alumni, demonstrating the strong collaborative spirit and co-building ecosystem among SCUT alumni enterprises.

Looking ahead, LinkToken will continue to leverage the SCUT alumni network to host more premium salons and in-depth coaching services focused on LinkedIn operations and international client acquisition. These initiatives aim to genuinely empower alumni enterprises in navigating the transformative journey from “Made in China” to “Global Brands.”

Company Profiles

LinkToken: Specializes in LinkedIn-based international customer development and brand globalization coaching services. We provide systematic training, customized strategies, and resource connections to help enterprises expand into global markets cost-effectively and efficiently.

Air Guard Purification Technology Group: Headquartered in Dongguan, Air Guard is a high-tech enterprise dedicated to the R&D and manufacturing of air purification technologies. With products exported to numerous countries and regions worldwide, it stands as one of the representative SCUT alumni enterprises committed to technology-driven global expansion.

Previous

Next