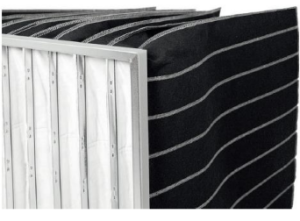

Filter Grade: M6~F7

Filter Media: Multi-layer filtration media with carbon cloth interlayer

Structure: Multi-layer synthetic filtration media with carbon cloth, sewn into a “V”-shaped configuration

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤450 Pa

Primary Applications: Suitable for the removal of low concentrations of chemically contaminated gases in air-conditioning ventilation systems.

Features:

Low resistance, suitable for high airflow

Broad-spectrum adsorption capabilities

Effective filtration of harmful gases such as SO2 and H2S

Food Manufacturing Industry

Air Guard CleanJoy Series Products: Ensuring Food Safety

Food Manufacturing Industry Solution

The Hazards of Bacterial Particulates in Air to the Food Industry

The hazards of bacterial particulates in air to food quality are multifaceted. To ensure the quality and safety of food, it is necessary to strengthen air environment management in all aspects of food processing and packaging lines, and strictly control the contamination of bacterial particulates in the environment.

The presence of bacterial particulates not only affects the taste of food but may also degrade the nutritional content within.

Food contaminated by harmful bacterial particulates in the air may lead to food safety incidents.

Bacterial particulates carry various enzymes and other biologically active substances, which accelerate the spoilage of food and significantly impact the shelf life of dairy products.

Certain populations with lower resistance are more susceptible to the impact of microbial contamination in food. Once they consume food contaminated by bacterial particulates in the air, it may lead to serious health issues.

Air Guard Customized Air Filtration Solutions for Food and Beverage Industry

Air Guard’s CleanJoy series of air filters, with high quality and efficiency, are deployed in fluidized bed dryers, aseptic filling lines, slicing, aging, and packaging processes to comprehensively protect food from spoilage and effectively mitigate the risks of product recalls and customer dissatisfaction.

Our comprehensive range of filters for the food industry, in conjunction with the clean systems within air handling units, ensures a clean environment in various areas, with high-cleanliness zones meeting ISO 5 cleanliness standards.

High-temperature sterilization is a crucial step, and Air Guard’s high-temperature filters designed for the food industry operate stably through the heating, constant temperature, and cooling stages, ensuring the elimination of bacteria in food and enhancing the shelf life of products.

Air Guard Practical Application Solutions and Advantages

After adopting Air Guard’s customized air filtration solutions, a food and beverage enterprise successfully addressed cross-contamination issues during production, enhancing product quality and employee efficiency.

The introduction of an intelligent air filtration management system enables the enterprise to monitor air quality in real-time and take timely measures to ensure a clean and hygienic production environment.

Fully compliant with ISO 846 standards (does not provide nutrients for fungi and bacteria, and exhibits inertness towards them)

The product can withstand the effects of disinfectants and cleansers without compromise.

Stable and reliable products reduce production downtime and product losses.

Maximizes operational excellence and extends product shelf life.

Food Manufacturing Industry Related Productions

Multi-Efficiency Pocket Filter

250°C High-Temperature Resistant Filter with Separator

过滤级别: H13~H14。

滤料:高温玻纤纤维

结构:不锈钢有隔板结构

连续运行温度:≤260℃

建议终阻力: ≤700Pa

主要应用:适用于高温隧道等高温净化的设备系统。

阻力低,稳定性强,持续高温运行,颗粒物去除效率>99.995%@MPPS

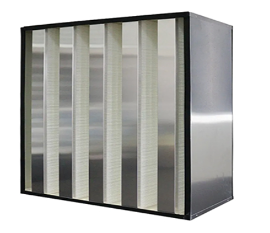

High Temperature Resistance V Bank Box Filter

Filter Grade: E10~H13

Filter Media: Double-layer high-density glass fiber material

Structure: “V”-shaped structure with high-temperature separator material

Continuous Operating Temperature: ≤120°C

Recommended Final Resistance: ≤650 Pa

Primary Applications: Suitable for use in high-temperature sterilization environments with fresh air in the food industry.

Features:

Low resistance, suitable for large airflow

Long service life

Particle removal efficiency >90%

Panel Filter without Separator

Filter Grade: E10~U16

Filter Media: Ultra-fine glass fiber material

Structure: Panel-type structure with pleats and no separators

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤350 Pa

Primary Applications: Suitable for the final air supply in cleanrooms of air-conditioning systems.

Features:

High efficiency, low resistance

Long service life

Particle removal efficiency >99.99995% @ MPPS (Most Penetrating Particle Size)

Middle Efficiency V Bank Filter

Filter Grade: M6~F9

Filter Media: Double-layer high-density glass fiber material

Structure: “W”-shaped structure for high airflow and increased filter media area

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤450 Pa

Primary Applications: Suitable for air-conditioning systems requiring high efficiency and high airflow or with limited installation space.

Features:

Low initial pressure drop

Long service life

Particle removal efficiency >98%

Panel Pre-filter

Filter Grade: M6~F9

Filter Media: Nanofiber layer

Structure: Corrugated deep-pleated filtration design

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤450 Pa

Fire Test: F1 DIN53438

Primary Applications: Suitable for use as the main filter in air-conditioning ventilation systems.

Features:

Corrugated nanofiber layer effectively reduces resistance

Deep-pleated filtration increases dust holding capacity

Consistent efficiency over time

Pocket Filter

Filter Grade: M5~F8

Filter Media: Multi-layer fluffy synthetic fiber cotton

Structure: Triangular “V”-shaped division and stitching technology

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤450 Pa

Primary Applications: Suitable for use as the main filter in air-conditioning ventilation systems.

Features:

Low initial pressure drop

Long service life

Particle removal efficiency >95%

Panel Pre-filter

Filter Grade: G3~M5

Filter Media: Double-layer synthetic fiber

Structure: Diversified structural design to cater to various application scenarios

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤250 Pa

Primary Applications: Suitable for pre-filtration units in the intake and exhaust systems of air-conditioning ventilation units.

Features:

Low initial pressure drop

Long service life

Particle removal efficiency >90%

Previous

Next