Filter Grade: M6~F9

Filter Media: Nanofiber Layer

Structure: Corrugated Deep-Pleated Filtration Design

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤450 Pa

Fire Test: F1 DIN53438 compliant

Primary Application: Suitable as the main filter in air conditioning unit ventilation systems

Features: The corrugated nanofiber layer effectively reduces resistance while the deep-pleated filtration design increases dust holding capacity. The efficiency remains consistent over time.

Data Center Industry

AGF CleanGate Series Products: Solving Air Particle Impurity Problems in Machine Room Environments

Data Center Industry Solution

The Hazards of Airborne Impurity Contamination to Data Centers

The impact of airborne impurity contamination on data centers is multifaceted, encompassing physical damage, operational stability, energy consumption, operational and maintenance costs, as well as environmental aspects.

• Increased Failure Rates: Airborne impurity contamination increases the failure rate of equipment within data centers, leading to frequent shutdowns and disrupting the stable operation of the data centers.

• Compromised Data Security: Equipment failures may result in data loss or corruption, posing a threat to the data security of data centers.

• Elevated Energy Consumption: Airborne impurity contamination can impair the heat dissipation of equipment within data centers, necessitating increased operational power of cooling equipment and thereby elevating energy consumption.

• Reduced Energy Efficiency: Impurity contamination affects the normal operational efficiency of equipment, resulting in decreased overall energy efficiency of data centers.

• Higher Maintenance Costs: Airborne impurity contamination increases the frequency and difficulty of equipment maintenance.

• Shortened Service Life: Impurity contamination accelerates the aging and damage of equipment.

AGF Customized Air Filtration Solutions for Data Centers

The AGF CleanGate series of air filters filter out dust in data centers, ensuring that the cleanliness of the data centers meets the ISO 8 standard of the ISO 14644-1 specification and complies with the GB50174-2017 design code for data centers, with the number of airborne particles greater than or equal to 0.5µm being less than 1.76×10^7 particles per cubic meter.

Maintaining a reliable communication network in industrial environments necessitates the use of chemical and dust filtration equipment to protect control rooms, which is the only way to meet this requirement.

AGF’s high-dust-holding-capacity F7 pocket filters enable air-conditioning units to achieve an ISO 8 cleanliness level in the output environment.

Air Guard’s coarse-efficiency G4 high-dust-holding filters protect precision air-conditioning units in data centers through internal recirculated air.

AGF’s molecular filters eliminate equipment failures caused by pollutants by targeting harmful gases such as SO2 and H2S, which are corrosive.

AGF Practical Application Solutions and Advantages

AGF collaborates with numerous air-conditioning manufacturers to provide tailored solutions for data centers in various environments across regions. These solutions are crucial measures to ensure stable data center operation, enhance work efficiency, and reduce operational costs.

Improved Air Quality: By safeguarding electronic equipment within data centers from corrosion, Air Guard helps maintain optimal air quality.

Enhanced Operational Reliability: Our solutions ensure the reliable operation of equipment, minimizing unexpected shutdowns and preventing business disruptions and financial losses.

High Dust Holding Capacity and Low Resistance Filters: By utilizing filters with high dust holding capacity and low resistance, Air Guard reduces energy consumption and significantly lowers operational costs for our clients.

Intelligent Management: Real-time monitoring of differential pressure and particle counts through intelligent management systems ensures the reliability of the data center’s operating environment.

.png)

Data Center Industry Related Productions

Panel Pre-Filter

Gas Adsorption Activated Carbon Module

High-Concentration Pollution, Long-Life Molecular Filter

Filter Media: Activated Carbon, Impregnated Activated Carbon, Impregnated Activated Alumina

Structure: “V”-shaped ABS or PET Outer Frame

Optimal Continuous Operating Temperature: 10-45°C

Optimal Continuous Operating Humidity: 40-90%

Primary Application: Suitable for high-concentration corrosive gases in electronic and electrical equipment

Material Selection: Can be customized based on different application sites and gas treatment requirements.

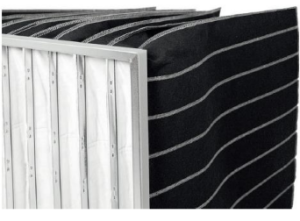

Multi-efficiency Pocket Filter

Filter Grade: M6~F7

Filter Media: Multi-layer Filter Media with Carbon Cloth Interlayer

Structure: Multi-layer synthetic filter media with carbon cloth interlayer sewn into a “V”-shaped configuration

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤450Pa

Primary Application: Suitable for the removal of low concentrations of chemically contaminated gases in air conditioning unit ventilation systems.

Features:

Low resistance, making it ideal for high airflow applications.

Broad-spectrum adsorption capabilities.

Effective filtration of harmful gases such as SO2 and H2S.

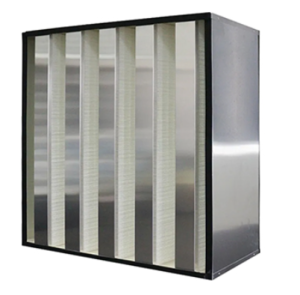

V Bank Box Filter

Filter Grade: F7~F8

Filter Media: Double-layer High-density Glass Fiber Material

Structure: “V”-shaped structure, with options for metal or plastic frames

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤450Pa

Primary Application: Suitable for air conditioning systems with high airflow and limited installation space.

Features:

Low resistance, making it ideal for high airflow applications.

Long service life.

Particle removal efficiency >90%.

Pocket Filter

Filter Grade: M5~F8

Filter Media: Multi-layer Fluffy Synthetic Fiber Cotton

Structure: Triangular “V”-shaped Segmented Stitching Technique

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤450 Pa

Primary Application: Suitable as the main filter in air conditioning unit ventilation systems.

Features: Low initial pressure drop, long service life, and particle removal efficiency >95%.

Pocket Filter

Filter Grade: G4~M6

Filter Media: Double-layer Synthetic Fiber

Structure: Ultrasonic Welded Filter Bags, Self-supporting Filter Bags

Continuous Operating Temperature: ≤70°C

Recommended Final Resistance: ≤250Pa

Features: Low initial pressure drop, long service life, high efficiency, and high dust holding capacity.

Primary Application: Suitable for pre-filtration devices in the initial stage of ventilation intake systems.

Panel Pre-Filter

Filter Grade: G3~M5

Filter Media: Double-layer Synthetic Fiber

Structure: Diversified structural design to cater to various application scenarios

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤250 Pa

Primary Application: Suitable as a pre-filtration device for the intake and exhaust systems of air conditioning unit ventilation.

Features:

Low initial pressure drop, ensuring energy efficiency.

Long service life, reducing maintenance costs.

Particle removal efficiency >90%, providing effective filtration.

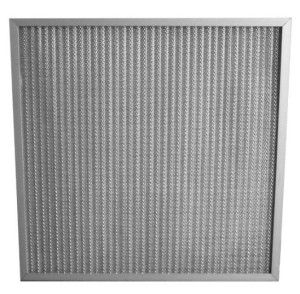

Metal Mesh Filter

Filter Grade: G2

Filter Media: Three-Dimensional Pleated Metal Mesh

Structure: Multi-layer corrugated filter screens stacked alternately

Continuous Operating Temperature: ≤300°C

Resistance: ≤10Pa

Recommended Service Life: Suitable for use in harsh environments, washable multiple times without the need for replacement.

Primary Application: Pre-filtration of large particles such as insects, mice, leaves, and pollen in the front section of the wall for fresh air systems.

Previous

Next