Filtration Grade: F7~F9

Filter Media: Nanocoated Material

Structure: Cylindrical Design with Easy Pulse-jet Back Blowing

Continuous Operating Temperature: ≤68°C

Primary Application: Suitable for Self-cleaning Filtration at the End of Gas Turbine Fresh Air Intake Systems

Features: Features self-cleaning pulse-jet injection function, resulting in a longer service cycle compared to conventional filters, thereby reducing overall costs.

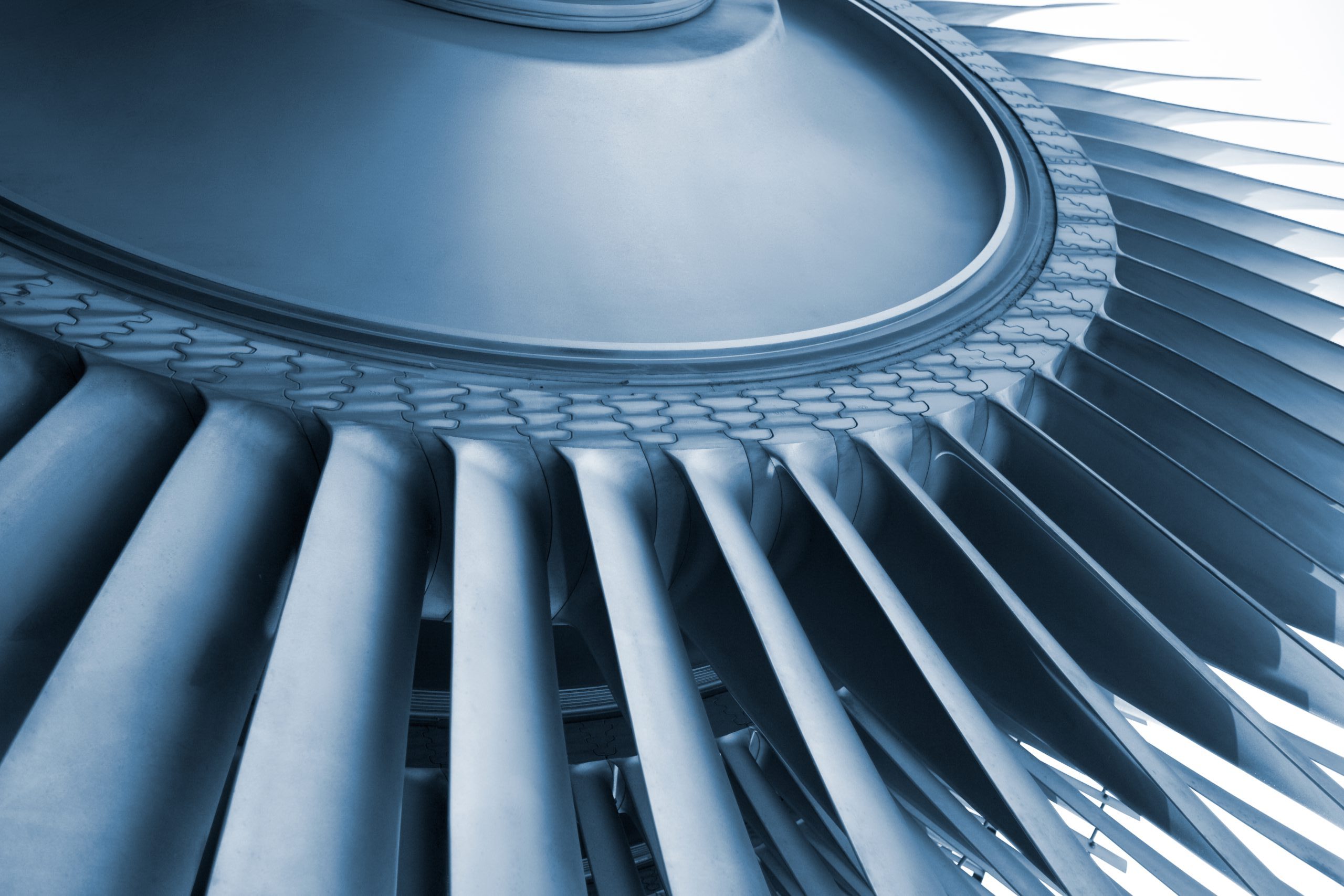

Gas Turbine Industry

AGF CleanPowel Series Products: Solving Blade Contamination and Erosion Problems

Gas Turbine Industry Solution

The Hazards of Microscopic Particulates in Air to Gas Turbine Inlet Systems

If the inlet filtration system fails to effectively filter the air to the expected standards, the compressor blades will face issues such as erosion and fouling, with fouling as an example!

• Fouling on blades can affect mechanical performance.

• It reduces unit efficiency, requiring more fuel to produce the same output.

• It alters the natural frequency of the blades.

• It leads to imbalance, causing excessive vibration.

• It increases the risk of surge or rotating stall.

• It clogs cooling holes.

• It raises component temperatures.

• Rule of thumb: An increase of +15°C can reduce the lifespan of metallic components by 50%.

In summary, the failure of the gas turbine inlet filtration system to effectively filter the air has severe consequences, including decreased gas turbine performance, accelerated wear and tear on unit components, and reduced economic benefits.

AGF’s Customized Air Filtration Solutions for Gas Turbine Inlet Systems

A minor improvement in gas turbine inlet filtration can lead to severalfold optimization in power generation unit performance. Our filtration solutions are designed to maximize the lifespan of gas turbine components and enhance their power generation efficiency.

AGF has invested significant research and development funds and manpower in seeking solutions to optimize and improve gas turbine performance. The AGF CleanKing series of air filters are used in various special environments.

In high dust environments, AGF’s coarse-efficiency plate filters and high-dust-holding capacity nano-pocket filters, matched in multiple stages, greatly reduce the maintenance and shutdown costs of gas turbines.

In high humidity environments, AGF’s coalescing and hydrophobic filters coalesce and separate moisture from the airflow, draining upstream to prevent dramatic resistance changes when the filters trap water.

AGF Practical Application Solutions and Advantages

Gas turbine filters must endure harsh operating conditions and ever-changing environmental factors. To ensure that the filters pose no risk of rupture during operation, AGF has enhanced the end filters with high-strength structures that can undergo various burst tests, ensuring safety, reliability, and stability.

Our products feature strong dehumidification, salt filtration, and moisture resistance, providing excellent protection for gas turbine turbines.

At the same efficiency level, our products offer low resistance, long service life, reduced replacement frequency, and lower maintenance costs.

We provide real-time detection with visualization and intelligence, including pressure difference alarm notifications, filter element replacement reminders, and recommendations.

Gas Turbine Industry Related Productions

Pulse-jet Cylindrical/Conical Filter

V-Bank Box Filter

Filtration Grade: F8~E12

Filter Media: Dual-layer High-density Glass Fiber Material

Structure: “V”-shaped Structure with High Airflow Inlet

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤650 Pa

Primary Application: Suitable for High-efficiency Filtration at the End of Gas Turbine Fresh Air Intake Systems

Features: Low Resistance, Suitable for High Airflow, Long Service Life, Particle Removal Efficiency >99.5%

V Bank Filter

Filtration Grade: F8~E12

Filter Media: Dual-layer High-Density Glass Fiber Material

Structure: “W”-shaped Deep Pleated Structure with Outlet Protection Mesh

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤650 Pa

Primary Application: Suitable for High-Efficiency Filtration at the Final Stage of Gas Turbine Fresh Air Intake Systems

Features: 40% Reduction in Initial Resistance, Long Service Life, High Burst Strength, Particle Removal Efficiency >99.5%

V Bank Filter

Filtration Grade: F8~E12

Filter Media: Dual-Layer High-Density Glass Fiber Material

Structure: “W”-Shaped Structure with Outlet Protection Mesh

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤650 Pa

Primary Application: High-Efficiency Filter for the Final Stage of Gas Turbine Fresh Air Intake Systems

Features: Low Initial Resistance, Long Service Life, High Burst Strength, Particle Removal Efficiency >99.5%

Pocket Filter

Filtration Grade: M6~F9

Filter Media: Glass Fiber

Structure: Gradually Increasing Structure for Deep Filtration

Continuous Operating Temperature: ≤250°C

Recommended Final Resistance: ≤450 Pa

Primary Application: Main Filter for HVAC Ventilation Systems, Extending the Lifespan of Downstream Filters

Deep Filtration with Fine Fiber Diameter for Increased Dust Holding Capacity and Prolonged Lifespan without Efficiency Decline

Panel Pre-filter

Filtration Grade: M6~F9

Filter Media: Nanofiber Layer

Structure: Corrugated Deep-pleated Filtration Design

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤450 Pa

Fire Resistance Test: F1 DIN53438

Primary Application: Suitable as the Primary Filter in Air Conditioning Unit Ventilation Systems, Extending the Service Life of Downstream Filters.

Features: The corrugated nanofiber layer effectively reduces resistance, while the deep-pleated filtration design increases dust holding capacity, ensuring consistent efficiency over time.

Pocket Filter

Filtration Grade: M5~F8

Filter Media: Multi-layer Fluffy Synthetic Fiber Cotton

Structure: Triangular “V”-shaped Segmented Sewing Technique

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤450 Pa

Primary Application: Suitable as the Main Filter in Air Conditioning Unit Ventilation Systems, Extending the Service Life of Downstream Filters.

Features: Low Initial Pressure Drop, Long Service Life, Particle Removal Efficiency >95%

Pocket Filter

Filtration Grade: G4~M6

Filter Media: Dual-Layer Synthetic Fiber

Structure: Ultrasonic Welded Filter Bag, Self-Supporting

Continuous Operating Temperature: ≤70°C

Recommended Final Resistance: ≤250 Pa

Features: Low Initial Pressure Drop, Long Service Life, High Efficiency, High Dust Holding Capacity

Primary Application: Pre-Filter for Ventilation Inlet Systems

Panel Pre-filter

Filtration Grade: G4-M5

Filter Media: Water-Repellent Synthetic Hydrophobic Fiber

Structure: Plastic Frame, Self-Supporting Material, Claw Separation

Continuous Operating Temperature: ≤70°C

Recommended Final Resistance: ≤250 Pa

Primary Application: Pre-Filter for Gas Turbine HVAC Inlet Systems in All Environments

Features: Specially Treated for Low Initial Resistance and High Dust Holding Capacity, with Inherent Water Resistance

Cardboard Pre-filter

Filtration Grade: G4

Filter Media: Dual-layer Synthetic Fiber

Structure: Waterproof paper frame with evenly spaced claws for segmentation

Continuous Operating Temperature: ≤68°C

Recommended Final Resistance: ≤250 Pa

Main Application: Suitable for use as a pre-filtration device in the inlet and exhaust systems of air conditioning unit ventilation.

Features: Non-hygroscopic, low initial pressure drop, long service life, and high structural strength

Previous

Next