Our Strengths

The R&D center of AGF Purification Technology Group adheres to professional, dedicated, scientific, rigorous spirit, keeping up with the world’s most advanced air purification and filtration technology. The introduction of advanced CFD simulation analysis software and professional testing equipment promotes our capabilities of product development and design higher, so that we can rapidly develop air purification and filtration products to meet customer performance requirements for the OEM, OES and IAM markets.

AGF R&D Center has fully participated into the project from the beginning of the development. Striving for excellence and perfection by data analysis through various experiments for continuous design optimization, and always trying to exceed ourselves.

PROFESSIONALTEAM

+

COMPLETESOLUTIONS

QUALITYEXPERIENCE

PRECISECRAFTSMANSHIP

Research & Development Capacity

In 2016, AGF established a research and development center and have our own independent R&D team, including 4 senior industry experts, 15 professional master’s degree R&D personnel and more than 30 engineers, 12 of them have senior and middle-level titles.

In May of 2019, AGF carried out deep industry university research cooperation with South China University of Technology, and established IUR Base and Advanced Air Purification Filter Material R&D Center.

In February of 2023, AGF jointly established Joint Laboratory of Filtration Media and Application Technology, Doctoral Research Center, Scientific Expert Workstation, IUR Base and Cultivation Base. We continiously promote the innovation of advanced filtration technology in automotive industry, industrial buildings, business buildings, public places, etc.

AGF R&D Center—CNAS Accredited Laboratory(CNAS No.:L18323)

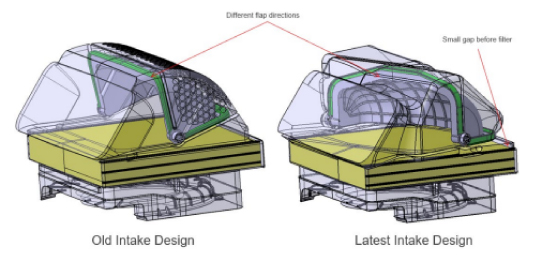

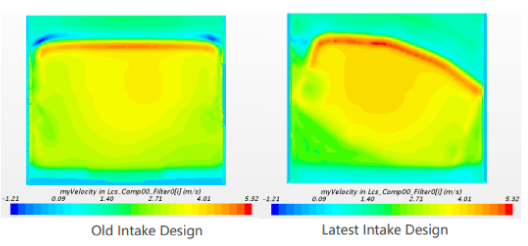

AGF CFD Fluid Analysis Capabilities

CFD, short for Computational Fluid Dynamics, is a simulation technology that virtually conducts experiments on fluid flow situations by solving differential equations that control fluid flow numerically. Its basic principle is to discretely distribute the flow field of fluid flow on a continuous domain by solving the differential equations that control fluid flow, thus approximating the simulation of fluid flow situations.

While developing new air purification products, engineers of AGF first use professional engineering software to build a 3D model of the product structure and define various standard technical requirements in the component library. After processing the product structure, they transfer it to CFD software, define the calculation method, and conduct CFD simulation analysis on the air conditioning inlet section. This can simulate the pressure drop performance of the air purification filter, the flow field and pressure field changes when gas passes through it, and establish a reliable model. By optimizing the design based on simulation results, they can significantly shorten the project development cycle and quickly and accurately design air purification products that meet customer performance requirements. They also assist customers in discovering the real reasons that affect various performance indicators during the product design process, thereby providing a complete air purification product solution.

Air Conditioning System

Before CFD Optimization

After CFD Optimization

Air Flow Analysis Diagram

Before CFD Optimization

After CFD Optimization

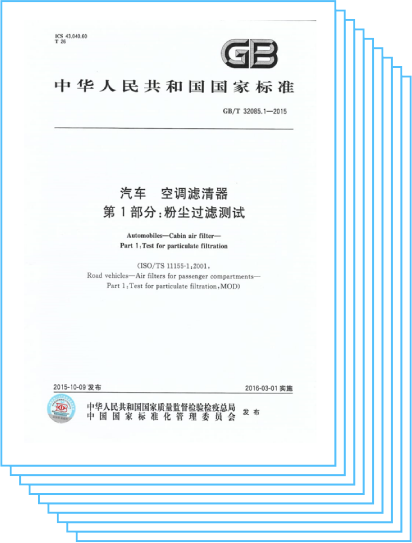

Standard Setting

AGF has carried out in-depth cooperation with the National Standardization Management Committee, National Automotive Standardization Technical Committee, China Automotive Engineering Research Institute, China Quality Inspection Association and other units, actively participated in the drafting and formulation of national standards and industry standards, and strived to promote industry reform and upgrading.

Quality Assurance

Strictly follow the IATF16949 quality system to implement closed-loop systematic quality control,ensure that the quality of each product meets customer requirements.

Supplier evaluation

Selection of quality compliant vendors

Raw material inspection

Rejected material insulation system

Patrol Inspection

IPQC Production line inspection process system

Product Evaluation

Continuous optimization and improvement

Shipment inspection

Unpacking and re-inspection before shipment

Quality assurance

Service commitment & after-sales guarantee system

Production Capacity

Main Equipment

Service & Commitment

We are committed to delivering value to our customers and creating value for society. We are dedicated to working with our partners to improve our air environment. To ensure that we provide the best air purification product solutions to our customers, we have established a professional laboratory and a research and development team with authoritative certification, air aerodynamics, gas pollutant and microbial antibacterial detection capabilities, as well as innovative spirit and efficient service. We have also established long-term and stable cooperative relationships with many universities and research institutions. In the early stage of project planning, our R&D engineers will maintain close communication with customers to ensure controllable processes, worry-free after-sales service, and continuous product improvement.

Feedback, Evaluation and Continuous Improvement (from the beginning to the end)

Plan and Identify Projects

Process design and Development Validation

Product and process Validation

Feedback、Evaluation、and Iontinuous improvement

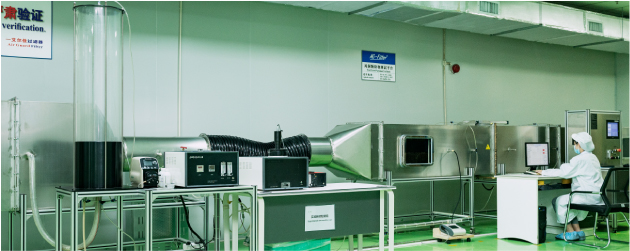

Laboratory Equipment

AGF R&D Center(CNAS Accredited Laboratory) has the most advanced filter test platform (Air volume 3,300 cubic meters), a comprehensive filter media test bench, a microbial test chamber, a particulate matter, and gaseous pollutant test chamber, and advanced gases test bench for adsorption efficiency and penetration rate. Test items include graded filtration efficiency, pressure drop, DHC, toluene, butane, nitrogen oxide and sulfide gas testing, microbial Escherichia coli, Staphylococcus aureus species, CADR clean air output ratio testing, CCM cumulative air purification Quantity testing, tensile testing, hot melt adhesive high and low temperature test and flame retardant performance test, etc.

3m3Test Chamber

30m3Test Chamber

Air volume 3,300m3 filter test platform

AGF Gaseous pollutant adsorption test bench

AGF Microbiology Laboratory